A popular book a few years ago was ingeniously titled, “Don’t Sweat the Small Stuff” and was a worldwide bestseller. The theme of the book was, “Don’t let the little things take over your life.” Great advice, almost.

Here is an example we can all relate to, you buy a new car and you take excellent care of the “big things”, the things everyone can see. The car is meticulously washed, the interior kept spotlessly and to everyone on the outside, it looks like a smooth-running machine. However, you make the decision not to “sweat the small stuff” so the tires begin to get worn and the oil is never changed. In comparison the value of the car these are seemingly negligible things to worry about until the tires blow out and/or the engine goes out. Then those small, ongoing maintenance investments take on an entirely different value.

I know you are probably thinking something like this, “Who would do that? Everyone knows that taking care of a vehicle so that it stands up to time requires small investments along the way to ensure it keeps running efficiently and safely.”

Common sense, right? Yet so many operators in the foodservice industry are so focused on the “curb appeal” of their establishments that they not paying attention to the “small stuff” that can literally put you out of business overnight

As anyone in the food service business knows it is precisely the “little things” that, if not routinely addressed through staff education and ongoing follow-up that can lead to disaster.

The reality is that most foodservice operators have a good idea of what it costs to train their staff, however many don’t ask themselves this simple question – What is the real cost of not training an employee?

Michael Leboeuf, Ph.D. author of “The Productivity Challenge” and “How to Win Customers and Keep Them for Life” offers this warning to businesses that overlook the value of staff training:

“If you believe that training is expensive, it is because you do not know what ignorance costs. Companies that have the loyalty of their employees (and customers) invest heavily in permanent training programs and promotion systems. ”

The challenge is that many foodservice operators see training as an investment that has any impact on profitability. This is short-sighted, to say the least, and in the long term a potentially dangerous mindset.

Untrained staff lacks the expertise to use resources properly, which always leads to waste. In the foodservice industry, a lack of knowledge about procedures affects, among others, food quality, inventory control, customer retention, overall profitability and potentially the safety of the food being served. All of which are devastating and destructive to your staff, your operation, and your customers. Everyone could potentially suffer.

Here are 5 reasons why poorly trained staff are costing you money . . . every day.

1) A Happy Staff is a Productive Staff . . .

Successful foodservice operators understand the business advantage of offering regular praise and routine training to their staff. There is a direct link between a happy staff and a successful establishment.

The current workforce understands the value of ongoing training and the opportunity for advancement. They feel that competition demands that they stay up to date and where possible get ahead of the curve in terms of personal development.

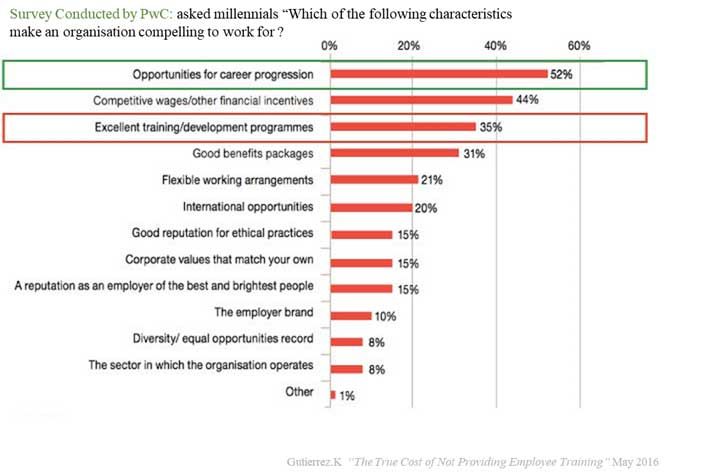

When asked in a recent Pricewaterhouse Coopers (PWC) survey, “Which of the following characteristics make an organization compelling to work for?” Below are their answers:

The flip side is that untrained and unhappy employees who feel unappreciated and underutilized are more likely to be frustrated in their job with little loyalty to their employer. This almost always translates into more mistakes, task failures, and an increasing unwillingness to meet even minimum standards.

Solid staff training also makes employees more efficient and productive in interactions with customers. Well trained staff can answer questions independently when they have a better understanding of their job and feel valued. This naturally produces more efficient work and a renewed ability to work effectively with management.

Side note – Yielding to or reducing organizational standards and expectations in response to an “unhappy” staff member in hopes of making them “happy” almost universally never works. In the long term, it can actually be to the detriment of the rest of your team. A system that is proven to work but is not for some reason is nearly always a result of either a poor organizational commitment to staff training, poorly delivered training or simply an unwillingness to follow procedures

Section 1.01

Section 1.02 2) Investing in Current Staff is More Cost Effective

Poor training leads to staff members who feel unappreciated and a feeling that their job doesn’t really matter. The result is usually they look for other employment or simply get terminated for poor work performance. Turnover may just seem to be a given in the foodservice industry but here is the reality – The hiring and onboarding of a new employee can initially cost as much as 30% of the job’s starting pay rate. This means that an employee that starts out at $25,000 a year could cost $7,500 to onboard according to a CDL Insight Consulting survey.

Properly planned “improvement” training for an existing employee usually cost significantly less (a few hundred dollars in most cases) and is much quicker. The reality is that while replacing one staff member may seem to be best, it is wise to understand that the real cost of hiring 3 new employees equal nearly one entire salary plus lost productivity during the onboarding period.

PeopleKeep.com estimates hiring costs alone to be no less than 12% of an efficient operation’s expenses and over 40% where there is a high turnover rate.

Studies indicate that for 70% of businesses, staff turnover has an impact on expenses because of the cost of recruiting, hiring, and training the newly hired employee along with overtime work incurred by current employees until the vacant position is filled.

Section 1.03 3) Smarter, Efficient, Profitable . . . Oh, My!

Does this really need much explanation? A food service operation is only as good as its team, and the team is only as good as the resources devoted to them. Poorly performing employees are a direct reflection of the organization’s commitment to its processes and staff education.

If you are having issues the first place to look is your training process, not your staff.

Proper training will make workers better and more capable of their jobs. This reduces staff redundancies of effort where many people are performing the same task. This can be due to poor training, but it can also be because management has not developed a “team” strategy, embraced working together or emphasized efficiency over independence.

The time and money to perform a task are greatly reduced when proven procedures are followed and the proper tools are provided to do the job right way, the first time.

The Wall Street Journal states that organizations who commit to and place a top priority on staff training have more than double the net annual revenue of those who do not. This is just the reality.

Human Resources Magazine reports that companies that commit to investing in routine, regular staff training see an average of 24% more profit than organizations who do not.

Like I stated before – Does this really need much explanation?

Section 1.04

Section 1.05

Section 1.06 4) Productivity = The Right Training

Staff training no longer means a weekend conference or a seminar at a local conference center. Technology now allows for training to be brought to you and in the format that best fits your needs.

Organizations should make it a priority to integrate processes that encourage and promote routine staff training in a manner that minimizes time away from work.

This is where online, web-based solutions like FoodHandlerSolutions.com can really help. A day-long classroom training can usually be reduced to a significantly shorter, self-paced, online course that allows the learner flexibility to take the course on their own terms.

These types of classes also increase retention of information because learners can review sections for increased understanding and course materials are generally broken up into segments that are more manageable.

The National Center on the Educational Quality of the Workforce (EQW) found that a small 10% increase in educational development produced an almost 9% gain in productivity and corresponding profitability. That is an almost dollar for dollar return on investment.

A commitment to effective, on-going training makes employees feel empowered and important in what they do, which naturally increases loyalty, engagement with the organization and ultimately increase productivity, efficiency, and profitability.

Section 1.07 5) It is ALL about the Bottom Line

Before you dismiss the need for routine staff training consider the risks and lost revenues involved by not having a commitment to training.

Lost productivity, staff turnover costs, negative inventory, and procedural impacts and lost customers due to the mistakes of poorly trained employees.

The success and ultimate survival of your operation are dependent on your staff, the effectiveness of their training and happiness in their job. Your customers see it and your bottom line reflects it. Believe it or not.

Cite: deloitte.com

Cite: deloitte.com